密相输送(又称正压输送)是一种借助压缩空气通过封闭管道输送干燥散装物料的工艺。在此工艺中,物料形成一个致密的塞子,在加压空气推动下沿管道移动。该技术尤其适用于输送易碎、易磨损的物料。

密相输送(又称正压输送)是一种借助压缩空气通过封闭管道输送干燥散装物料的工艺。在此工艺中,物料形成一个致密的塞子,在加压空气推动下沿管道移动。该技术尤其适用于输送易碎、易磨损的物料。

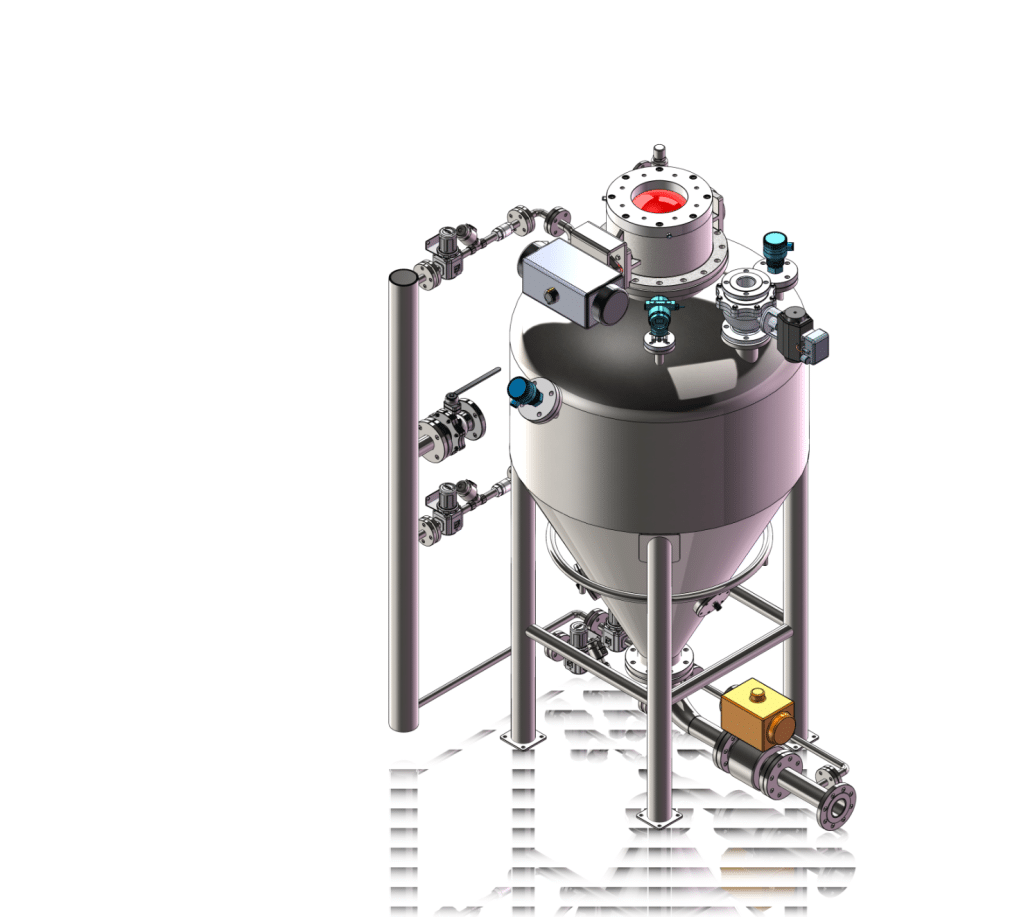

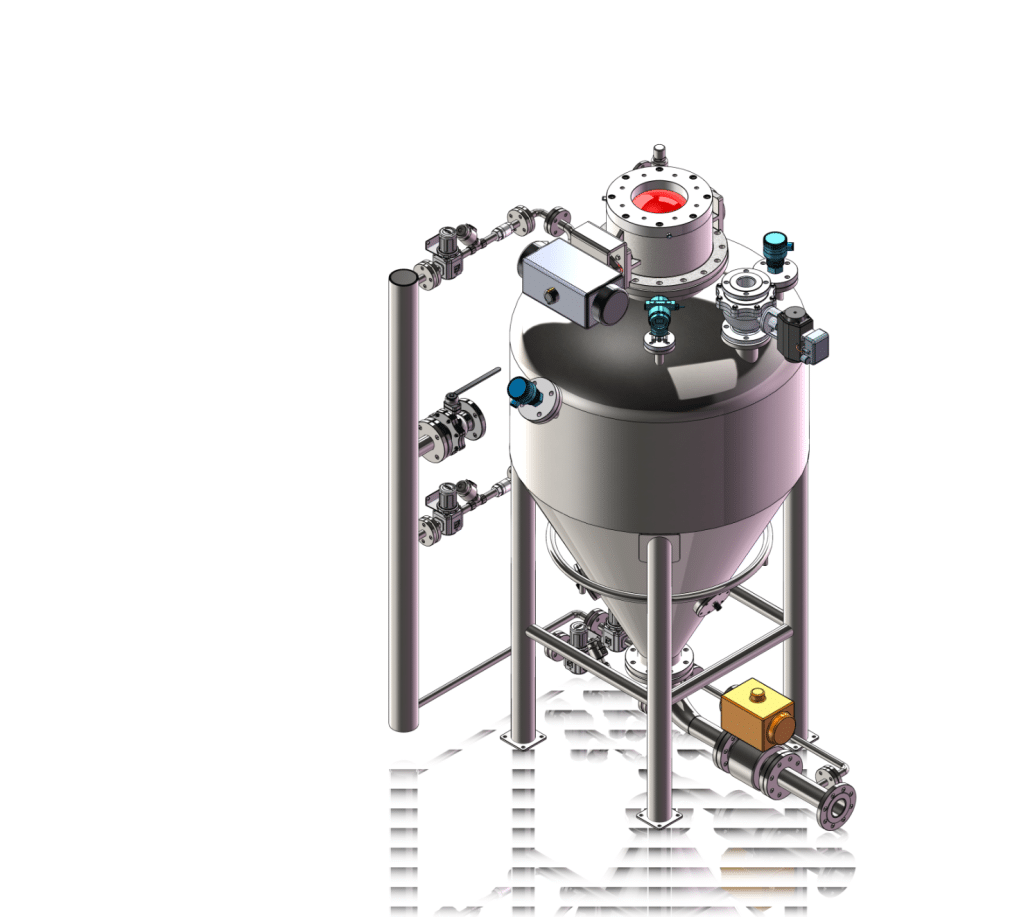

正压密相气力输送装置是一种利用发送罐推动物料的先进物料输送系统。这种创新系统利用超过1kg/cm2的气源压力,高效地将物料推过输送管道。

这种气力输送装置的显著特点之一是可在低气体流量下运行,从而有助于提高能源效率。系统设计通过优化气流路径,最大限度降低输送管道磨损,有效延长管道使用寿命并增强可靠性。输送泵设备被称为气流输送,利用气流的能量来促进水平、垂直或倾斜的物料输送。这种多功能方法增加了系统在不同方向的适应性,使其成为各类需要高效可靠物料输送行业的理想解决方案。

能源效率和环境影响:密相输送系统以低能耗运行著称,相比传统输送方式,是更经济且环保的解决方案。其节能特性不仅降低运营成本,更契合可持续发展目标。

物料处理专业知识:密相输送系统以其温和的处理能力而闻名,擅长运输粒度小于2毫米的易碎颗粒材料和粉末。通过可控输送过程,显著减少物料破损或降解,全程保障材料完整性。

通过减少磨损延长使用寿命:密相输送系统内固体材料的受控移动可显著减少管道磨损。这一特性可最大限度地减少磨损,延长输送系统的使用寿命,并有助于长期节省成本。

高效除尘性能:密相输送系统在除尘方面表现出色,这得益于其较小的输送风量和较低的能耗。这种效率简化了分离和除尘过程,营造了更清洁、更安全的工作环境。

保持材料完整性:通过在运输过程中保持低速和稳定条件,密相输送系统可防止材料降解。这一特性对于精细材料尤为重要,可确保在整个运输过程中保持其完整性。

材料混合的均匀性:密相输送通过确保以相似的速度输送不同成分,最大限度地减少了混合材料的分离。这种细致的方法可以保持混合物的均匀性,在整个运输过程中保持一致性。

优化维护效率:密相输送系统在低速下运行时,管道磨损最小,从而延长管道寿命并减少维护频率。这意味着停机时间和总体维护成本降低,从而提高运营效率。

紧凑型辅助设备:密相输送系统的低空气消耗特性使系统可适配小型化过滤器、压缩机及干燥机,不仅降低初始安装成本,更通过简化维护流程提升整体性价比。

正压系统中的密相输送涉及在压力大于 30 psig (~2 barg) 的情况下移动材料,固体负载量超过每磅气体 15 磅固体。密相输送的关键规格包括

密相输送的特点是速度低、压力高、产品与空气的比率高。与稀相系统相比,它具有以下优势:减少部件磨损、降低运营成本、基本维护以及减少材料分离和降解。

幽威密相正压输送仓泵适用于输送生产能力大、比重大、颗粒度大、硬度低的粉料,设计等效输送距离一般≤1000m,垂直爬升60m,粉料比重≤6.0t/m³,粉料粒径≤5.0mm,粉料最高瞬时温度≤200℃,适用于单点或多点卸料工况。

幽威密相正压输送仓泵,以压缩空气为动力,是电厂气力除灰系统中较早使用的气力输送设备之一。泵底部装有流化板,对泵内粉料加压流化,达到设定压力值后,卸料阀自动打开,粉料在流化和压差作用下,高速进入输送管道,达到粉料输送的目的。

此泵为沸腾结构,打开出料阀时,初始流速较高,不适用于输送磨蚀性强、硬度大的粉状物料。但物料特性及输送距离允许时,也可先打开出料阀,再打开气源控制阀,使物料在流化的同时以较低的流速进入输送管道,可有效减少出料阀及出料管的磨损。由于物料初始流速较低,不适用于长距离输送。

幽威密相正压输送仓泵适用于输送产量大、比重大、粒度大、磨蚀性强、硬度大的粉状物料。输送磨蚀性强、硬度大的粉状物料,需采用复合陶瓷耐磨管道。设计等效输送距离。

请立即联系我们的专业销售团队!我们将在 2-3 小时内回复您。

我们是一家专业从事粉体物料输送自动化的公司,为客户提供完整的工程设计与交付、核心设备及配件、自动控制软件和技术服务。

给我们留言,我们会在2-3小时内回复留言!